Technology is constantly evolving and while infrared thermography is not a brand-new tool, maintenance and facility managers may be unaware of its full potential for cutting costs and lowering the risks to your building and business. The infrared thermography industry is expected to grow 9.5 per cent per year until 2027, with more and more maintenance and property managers using this technology to manage their properties better.

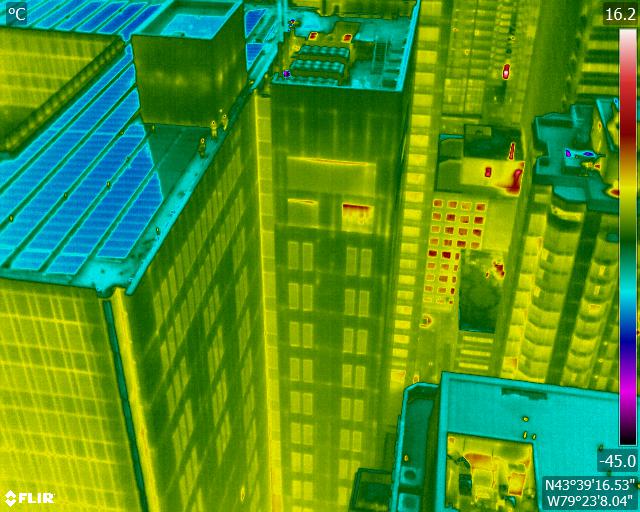

What is infrared thermography? This type of technology works by identifying and capturing temperature differential in a photo, demonstrating potential issues in your building. Thermography exposes concerns in your roof and walls, and within your electrical system that are not visible to the naked eye. This technology helps to identify issues before they become critical, allowing you to correct potential failures before larger problems occur.

Your roof

Infrared thermography serves as a non-destructive diagnostic tool, identifying moisture in your roof system by highlighting areas of wet insulation that hold the heat during the day. For the most accurate results, roof scans should be completed when it is 15˚ C or warmer during the day (without rain) and when an 8˚ C difference exists between the daytime high and the time of the scan. This temperature differential exists most commonly from late spring to early fall.

What’s involved in a thermal roof scan? A certified thermographer will take thermographs at night, note the areas that appear wet within your roofing system, and re-visit during the daytime to verify that those areas are in fact wet, using a moisture probe. All roofs with exposed membranes can be scanned, making this an effective investigative tool for most roofing systems.

Infrared thermography can help you identify areas on your roof that need attention and help you budget accordingly, but it’s a tool that can cut costs in other ways, too. Often when issues start occurring with older roofs, the assumption is that a major repair or replacement is imminent, however, a roof scan can help you avoid unnecessary spending by identifying small areas that need repair. “Even with an old roof, if you can determine that only 4 per cent of that roof is wet, why replace 96 per cent of dry roof before you need to?” asks Brian Jastrow, Principal at InfraRed Imaging Solutions Inc (IRIS).

RELATED: Keeping your building air and watertight

Your walls

As part of your building envelope, certain issues in your walls can also be identified with an infrared scan. A wall scan is the process of testing the physical separator between the interior and exterior of a building to determine if there are any air, water, or thermal leaks within the structure.

These scans are completed in 2 phases. The first phase occurs when the building is under negative pressure and demonstrates conductive heat loss. The second phase takes place when the building is under positive pressure, demonstrating where air leakage exists.

Wall scans are best conducted in the winter when the building’s temperature is higher than the temperature outside. When the technician returns to verify areas of air and heat loss, they can locate the source of the leak, identify the cause, and recommend steps for repair. Issues could include anything from missing caulking to a hole in the wall, insufficient insulation, thermal air bridging, and beyond. Many of these issues are simple, often inexpensive repairs, saving you money and increasing your building’s efficiency over the long term.

Your electrical panels

Infrared thermography works similarly on electrical panels, identifying problematic areas within the electrical system, even while the system is still in service. Electrical scans are conducted to identify whether any electrical connections are overheating, energy efficiency is down, or a safety hazard exists, helping you avoid a potential fire by preventing an electrical failure. These can be dangerous, possibly fatal, and often expensive concerns for building owners.

These types of scans consist of 3 phases: a, b, and c, identifying issues like loose lug connections, bad fuses, and more. These potentially dangerous issues create resistance and heat, easily identified by the infrared camera.

Unlike roof scans, electrical panels can be photographed any time of year, and all types of panels can be scanned. Jastrow recommends an annual scan to determine benchmarks and stay on top of developing hazards, explaining that some managers like to alternate between summer when the chillers are running and winter to evaluate the heating system as a whole. Similarly, mechanical motors including any equipment up to 74 horsepower, ranging from elevator machine motors to chillers can also be scanned.

Infrared thermography serves as a predictive diagnostic tool saving facility and maintenance managers money, headaches, and income lost to unexpected shutdowns or costly repair or replacement.

What you need to know

If you are new to the infrared realm, there are some things to take into consideration before settling on a technician. Here are some questions to ask when looking at investing in an infrared scan:

- What are the qualifications of the technician? Thermographers are qualified in three levels (levels one, two, and three). Use these levels to determine the best fit for your needs.

- What are their specialities? Along with the thermography certification, you want someone who can properly interpret the results, so roofing, building envelope, and electrical experience should be a requirement as part of your elimination process.

- What is the quality of the equipment they use? Higher quality equipment means clearer images and a more specific look at any troublesome areas in your building. Requesting to see previous reports can help you get an idea of the quality of the images you will receive.

- How available is your technician? Issues with your building don’t always happen during the workday, of course, so look for experts who will be available when you need them most.

Think your building is “too new” to benefit from this type of technology? Even new equipment and roofs should be scanned. “Infrared thermography is a preventative tool to save you from expensive repairs, replacement or worse,” says Jastrow, explaining there may be a tendency to skip a scan due to a system that seems to be working well. However, as he points out, “You can drive your car every day and nothing happens to you, until one day, something goes wrong.” This same philosophy applies to maintenance management and taking advantage of technology like infrared thermography to practice a proactive approach to your building.

Infrared thermography is a tool to help maintenance and facility managers understand more about their buildings. Scans can be an annual line in your budget, allowing you to benchmark and plan for the deterioration of these assets, avoid costly surprises, and protect the people and property in your building.